We provide solutions for material feeding, automatic screw fastening, automated assembly, inspection, and product unloading for consumer electronics such as smartphones, tablets, computers, and gaming devices.

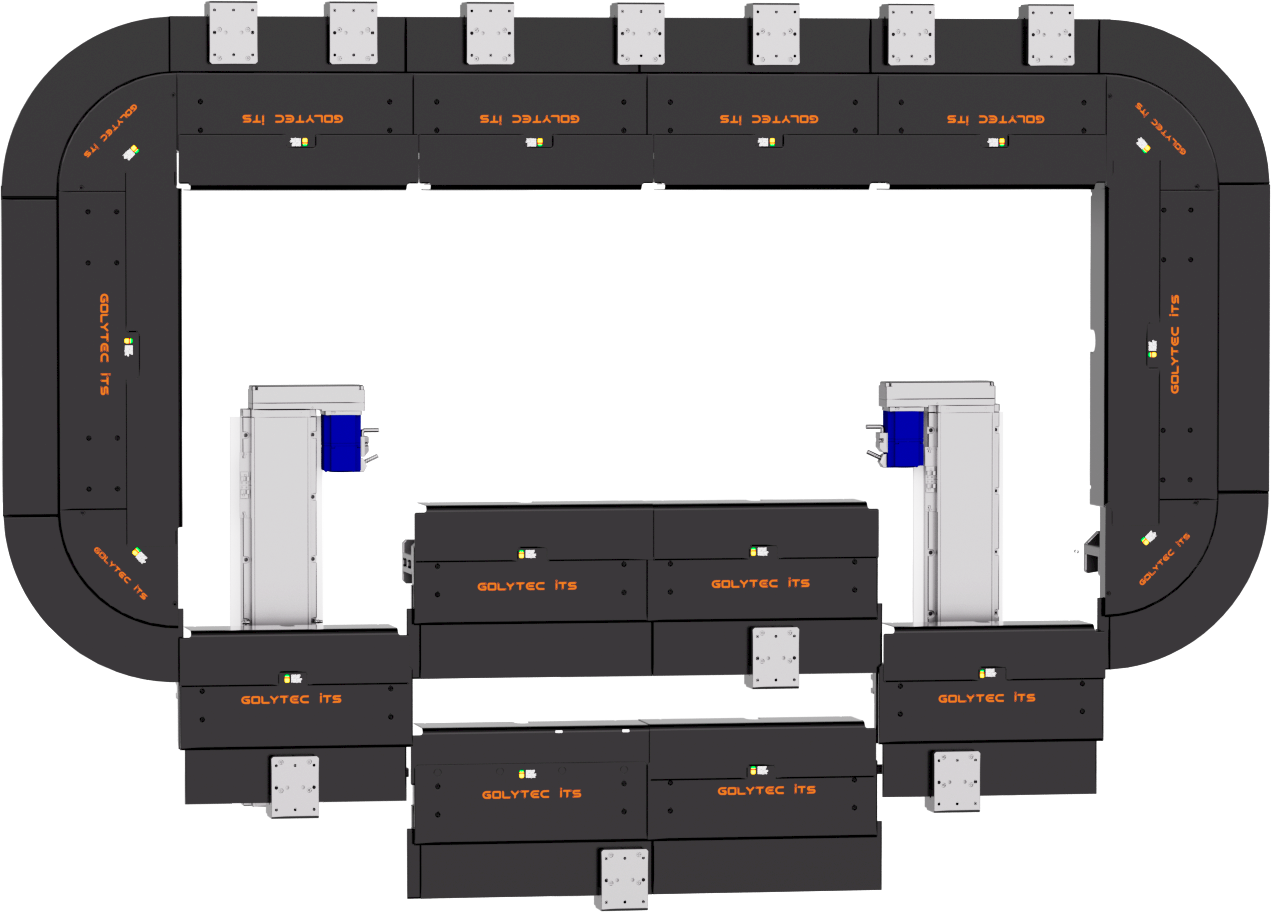

We can provide fully automated flexible assembly stations and turnkey production line solutions. include flexible feeding, assembly, screw fastening, laser marking, soldering, labeling, inspection, and other key processes.

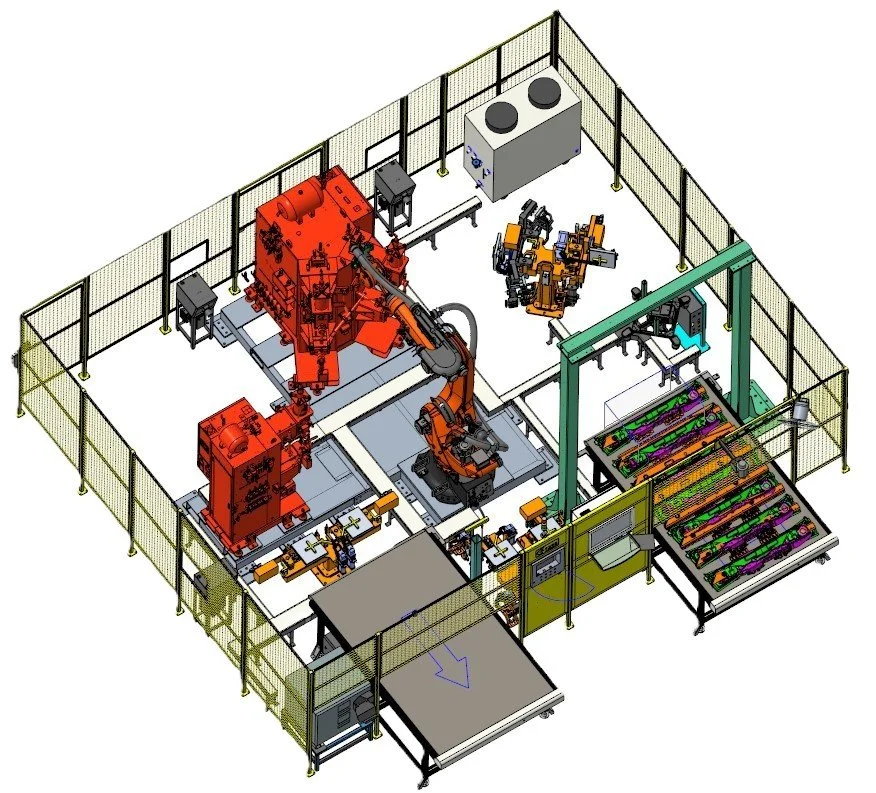

In the automotive sector, the team has many years of relevant R&D experience and can provide both traditional automated production line solutions and flexible modular production lines as turnkey applications.

To meet the handling requirements in the medical sector, we also provide various flexible automation solutions, including flexible feeding, sorting, inspection, and cleanroom-compatible applications

In the toy industry, We offering a wide range of solutions including automated assembly, inspection, packaging, and automated logistics.

We offers a wide range of customized R&D services, with successful solutions across multiple industries including photovoltaics, aquaculture, hardware manufacturing, and metal stamping

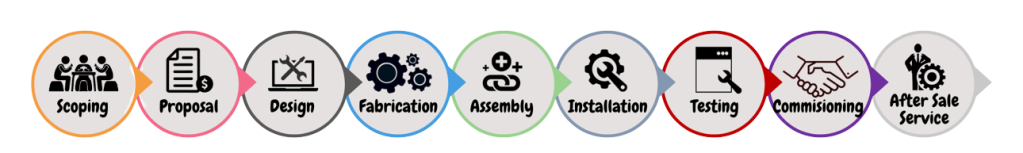

HOW WE WORK

OUR CLIENT

APM AUTOMOTIVE

•

BLOXWICH MALAYSIA

•

JEMCO MANUFACTURING

•

BELTON AUTOMOTIVE

•

HEXTON MANUFACTURING

•

SIRIM MALAYSIA

•

GSG CONCECRETE

•

TEKUN CONCRETE

•

EVE ENERGY

•

FONXCON TECHNOLOGY

•

LUXSHARE TECHNOLOGY

•

TE CONNECTIVITY

•

APM AUTOMOTIVE • BLOXWICH MALAYSIA • JEMCO MANUFACTURING • BELTON AUTOMOTIVE • HEXTON MANUFACTURING • SIRIM MALAYSIA • GSG CONCECRETE • TEKUN CONCRETE • EVE ENERGY • FONXCON TECHNOLOGY • LUXSHARE TECHNOLOGY • TE CONNECTIVITY •

Camos Automation Sdn Bhd is a professional automation solutions provider specialising in custom-designed machinery and integrated systems for industrial applications. We leverage state-of-the-art automation technology to support a wide range of sectors, including Heavy Construction Steel Processing, General Metal Work Processing, and advanced Welding Technologies such as Resistance Welding and MIG Welding.

Backed by years of hands-on experience, our engineering team delivers reliable and efficient automation solutions with strong system integration capabilities. We apply key technologies such as 4/6-axis robotic systems, mechanical cam mechanisms, 2D/3D vision systems, and flexible feeder technologies to optimise production efficiency, accuracy, and consistency.

Beyond hardware solutions, we also provide comprehensive automation software services, including PLC & HMI programming, robotic system integration, and PLC troubleshooting support for both end users and partner machine integrators. Our focus is to enhance productivity, reduce downtime, and ensure long-term operational stability for our clients.

At Camos Automation, we are committed to transforming complex manufacturing challenges into smart, efficient, and scalable automation solutions.